Here at DLS we stand, like most, incredulous at the events unfolding in Ukraine. As Vladimir Putin and his henchmen stamp around creating havoc the feeling of powerlessness is hugely frustrating. At the same time the Russian population seems oblivious to the damage that Putin is doing to the very way of life that they have become used to! What can we do to help?

Here at DLS we stand, like most, incredulous at the events unfolding in Ukraine. As Vladimir Putin and his henchmen stamp around creating havoc the feeling of powerlessness is hugely frustrating. At the same time the Russian population seems oblivious to the damage that Putin is doing to the very way of life that they have become used to! What can we do to help?

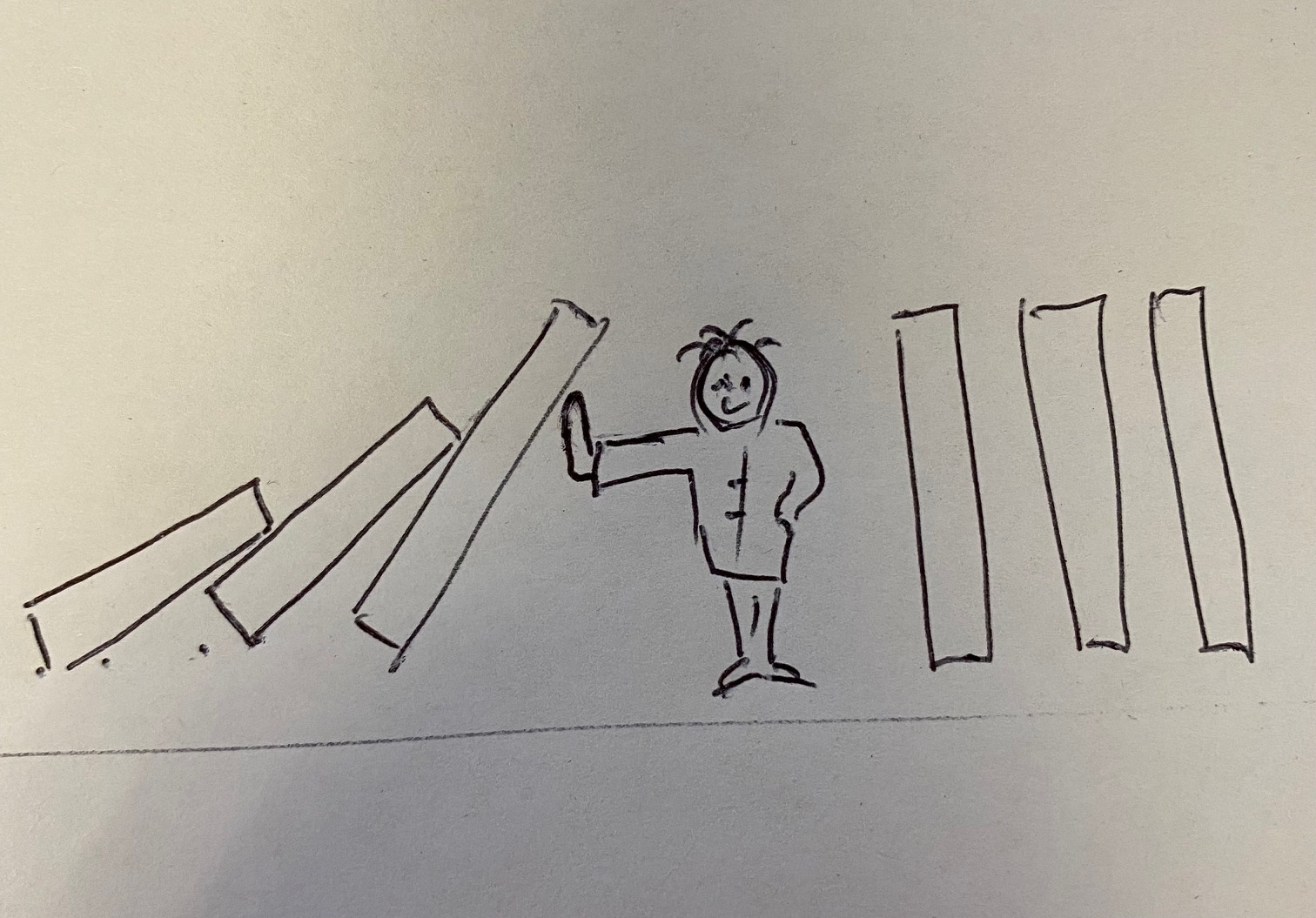

At DLS Medical we are donating medical supplies, PPE and hygiene packs to a local haulier P C Howards who will deliver these to the Ukrainian people along with our solidarity and sincere wish that this madness comes to an end soon.

And a side message to all those Russian hacker sites that fill up the comment database of this blog site – get lost will you? Honestly, haven’t you got better things to do?