According to the United Nations Human Rights Council, Internet access is now a basic human right and they condemn any country that restricts or disrupts their citizen’s access to the world wide web. Rating Internet access just below physiological needs such as shelter, air, food and water shows just how reliant modern society is on gadgets and connectivity.

With advances in technology being made every day, its easy to forget and overlook the simpler things in life – the cornerstones and core components of the world that have been effectively doing their job effortlessly for decades.

Designed to be robust, lightweight and strong, the DLS range of corner joints is just one of these components. Manufactured in the UK, our Single and Double Corner Joints with lids are sold and despatched to destinations all around the world. These uncomplicated but resilient brackets can create a strong and rigid joint between two pieces of wood with the addition of two screws, then simply press the lid into place to hide the fixings and leave it to do its job. Its this straightforward concept that makes the corner joint so dependable and popular, with over 1 million units being manufactured and sold every year. DLS is able to supply both the Single and Double Corner Joints in a plethora of stock colours, but also offer a colour matching service for customers requiring a unique finish whilst maintaining excellent value for money .

So next time you sit down at your desk to access the internet or work on your latest project, spare a thought for the humble corner joint holding that piece of furniture together and consider whether your product would benefit from the strength, support and reliability of a DLS Corner Joint.

Call the DLS Plastics Sales Team today on 01476 564549.

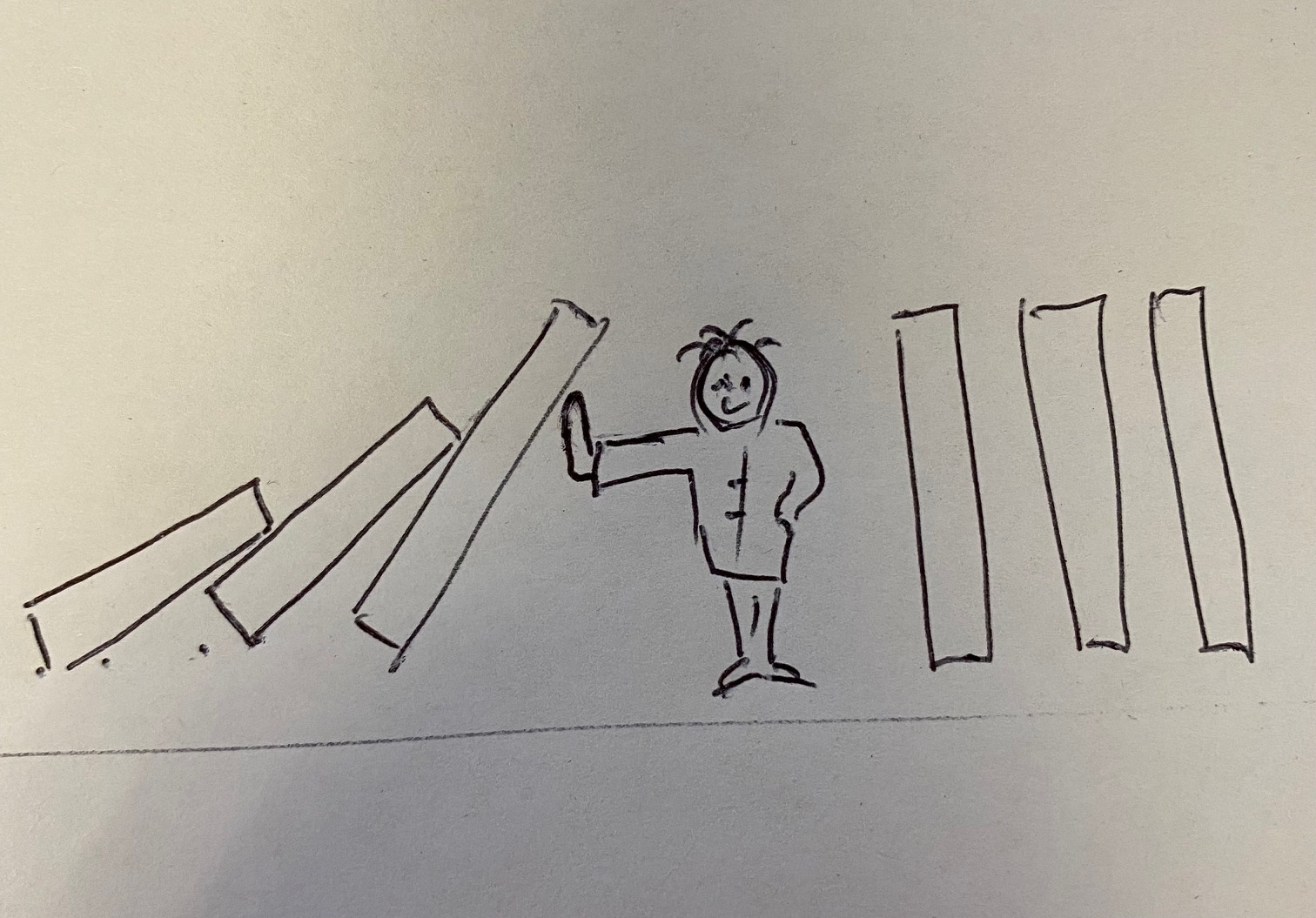

Here at DLS we stand, like most, incredulous at the events unfolding in Ukraine. As Vladimir Putin and his henchmen stamp around creating havoc the feeling of powerlessness is hugely frustrating. At the same time the Russian population seems oblivious to the damage that Putin is doing to the very way of life that they have become used to! What can we do to help?

Here at DLS we stand, like most, incredulous at the events unfolding in Ukraine. As Vladimir Putin and his henchmen stamp around creating havoc the feeling of powerlessness is hugely frustrating. At the same time the Russian population seems oblivious to the damage that Putin is doing to the very way of life that they have become used to! What can we do to help?